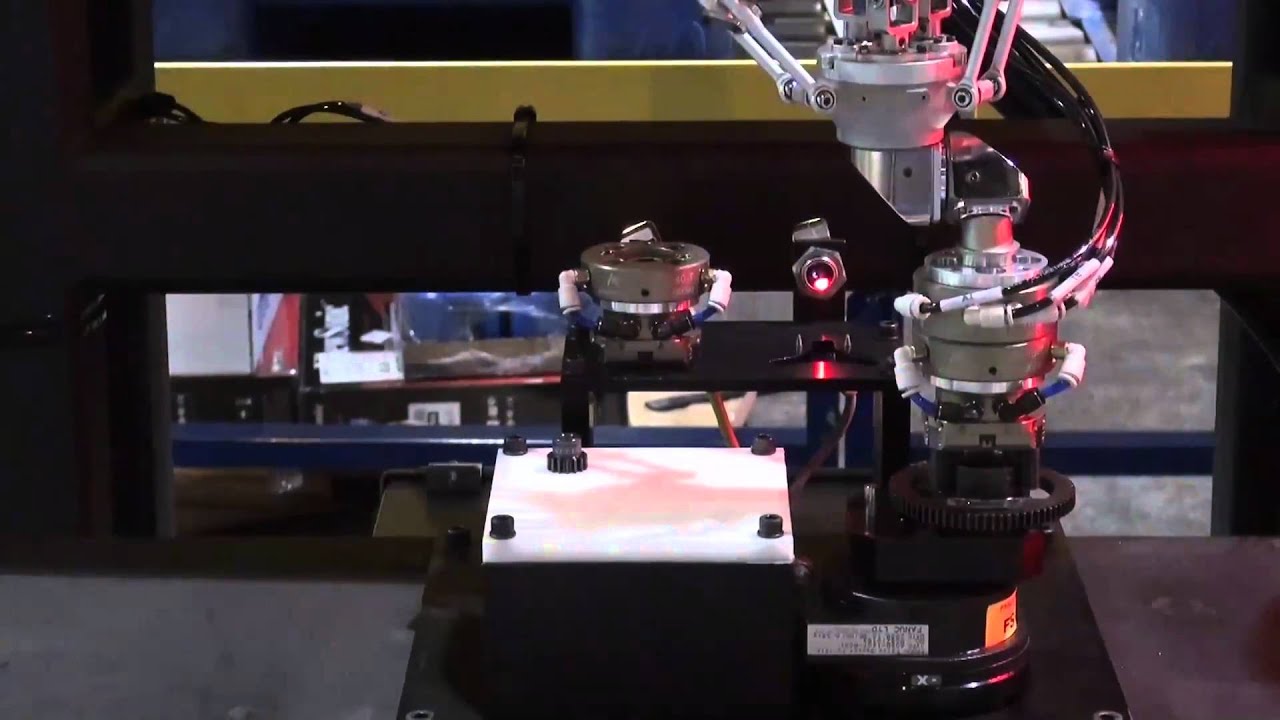

FANUC America Corporation

Gear assembly process – http://www.fanucrobotics.com/Assembly/

A FANUC M-1iA robot performs gear assembly using 2D iRVision and Force Sensing. With 2D iRVision, the robot locates the two different gear models. The robot then selects the appropriate tool to pick the particular gear needed to start the assembly. The robot moves to a fixture equipped with an FS-15iA force sensor and assembles the gear onto a shaft. Then the robot changes grippers to pick and assemble the other gear onto a shaft with face match. The flexibility, speed, and accuracy of the M-1iA allows for precision gear placement. The 2d iRVison allows the robot to locate gears of different sizes. The capabilities of the new FS-15iA allow for precision force measurement for properly assembling the gears.

http://www.fanucrobotics.com FANUC Robotics America Corporation designs, engineers and manufactures industrial robots and robotic systems for a wide range of applications including arc and spot welding, material handling (machine tending, picking, packing, palletizing), material removal, assembly, paint finishing and dispensing. The company also provides application-specific software, controls, vision products, and complete support services. After 28 years of success, FANUC Robotics maintains its position as the leading robotics company in the Americas.

Source