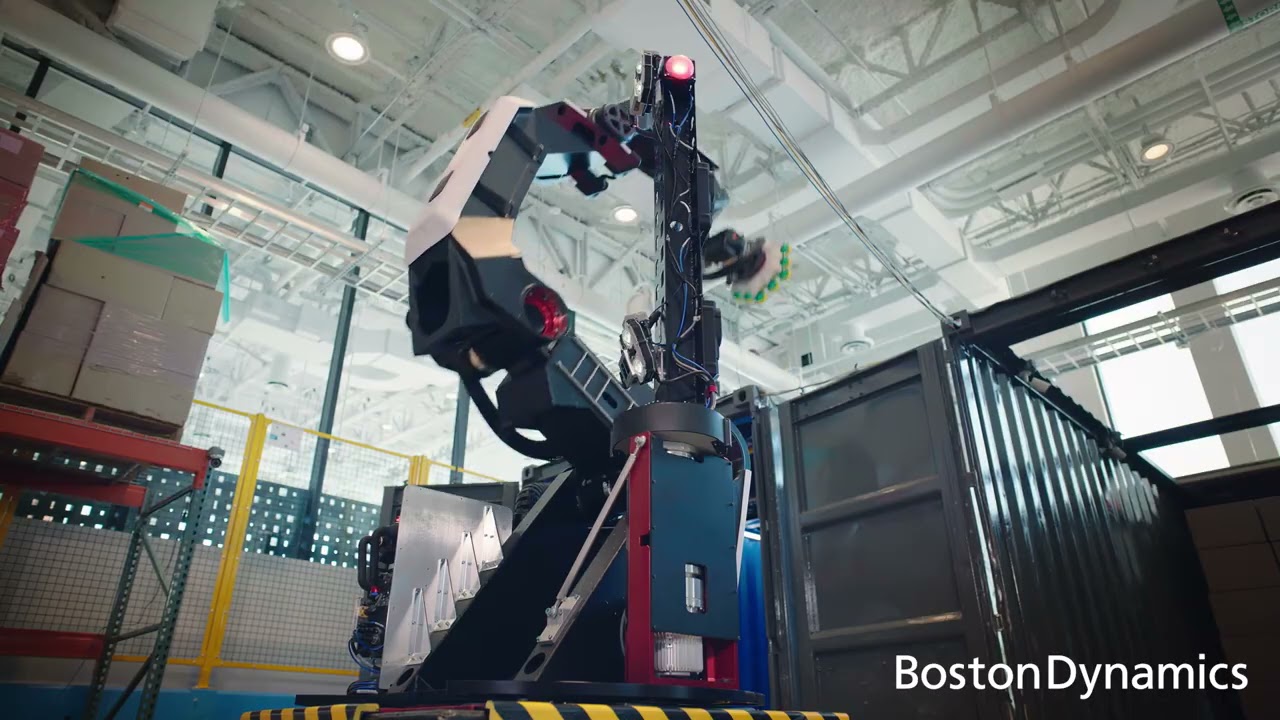

Boston Dynamics

How is Stretch tackling one of the toughest jobs in the warehouse? With an advanced vision system, a smart gripper, speed, and strength, our automated case handling robot Stretch does the heavy lifting to safely unload trailers and containers.

To discover how container unloading strengthens the supply chain, visit: https://bosdyn.co/3FfTZJL

To learn more about Stretch, visit: https://bosdyn.co/3rV4gb8

Source

Two shifts on one battery… Wow, thats impressively efficient.

But what if a conveyor belt isn't available?

I want one so I can build LEGO sets faster

Der takin er jerbs

Carol Tome doing backflips rn

To all those whining in comments:

Keep inventing an edge cases, meatbag. Those are like 1% of the whole volume of work. And we are proud to leave them for ya to unload.

Very nice 👍

Why so big and clunky? This was the most ergonomic design you were able to think of?

Anyone who has ever had to do this for 8 hours in a hot warehouse is down on their knees thanking you for this innovation. Let's hope it gets implemented in a smart way.

How heavy of a load can it lift. All those boxes gave a small bounce, like they are all empty…

So if it's named Stretch, and that's "SA-19", is it's last name "Armstrong"? 🙂

Okay so here it is. And the guy behind the computer is I'm behind the control and all. That was supposed to say control panel but I will go with anal. You guys got this on the other and don't post it. If you do hear you got bigger balls than me 🏁💯🎯

The poor people of that warehouse was unpacking their replacements

Your guys commercials used to be awesome

Pretty cool, but can it work faster than a person can safely work? Because thats how fast people do those jobs already

So when are we getting UBI? 🤔

Good stuff! but the vid looks somewhat familar to a previous video released earlier this year.

Lol, did this job for the home depot for a while, never saw a trailer that didn't look like it had just driven off a cliff before it got to us.

None of the boxes are ever stacked like that and they’re never the same size plus, they’re not even interlocked this isn’t very realistic.

I wonder if it can pick up a Family sized fridge upright.

Boston Dynamics is doing very badly with android robots if they have taken up the outdated technologies of robotic manipulators from the 70s and 80s of the last century.

사람보다 비싸면 일자리를 빼앗지 않으니 여전히 윤리적입니다. 웃음

Having worked in a very big shipping hub, I can say for a fact, very few, if any trailers come in loaded like that! Even if the trailer was loaded by a robot, boxes just don’t stack like that, they are all over the place in size, weight and material. It’s a crappy job and having a robot to do it would be great but I don’t think it’d save much in manpower as you’d need someone there to do all the odd shaped and damaged stuff. A robot can’t handle a parcel and know the box is pretty thin, and the weight is all concentrated in one place, so might fail if you don’t support it from the bottom as you lift it. I think any time saved using robots, would be spent clearing up spills and damaged goods.

amazing

All pretty and sweet, when boxes are nicely put inside container xD.